Hydronic System Fill Valves – Establishing Proper System Pressures

By: Paul Campbell, Corporate Trainer, CHC

Who cares about Fill Valves, also known as Pressure Reducing Valves for a closed loop hydronic system? If you’d like a quiet heating or cooling system, pumps that operate correctly, boilers/chillers that add heat/cooling to the system, and happy occupants of the home and/or building…then you should pay attention to that small device in your mechanical room called a Fill Valve or PRV.

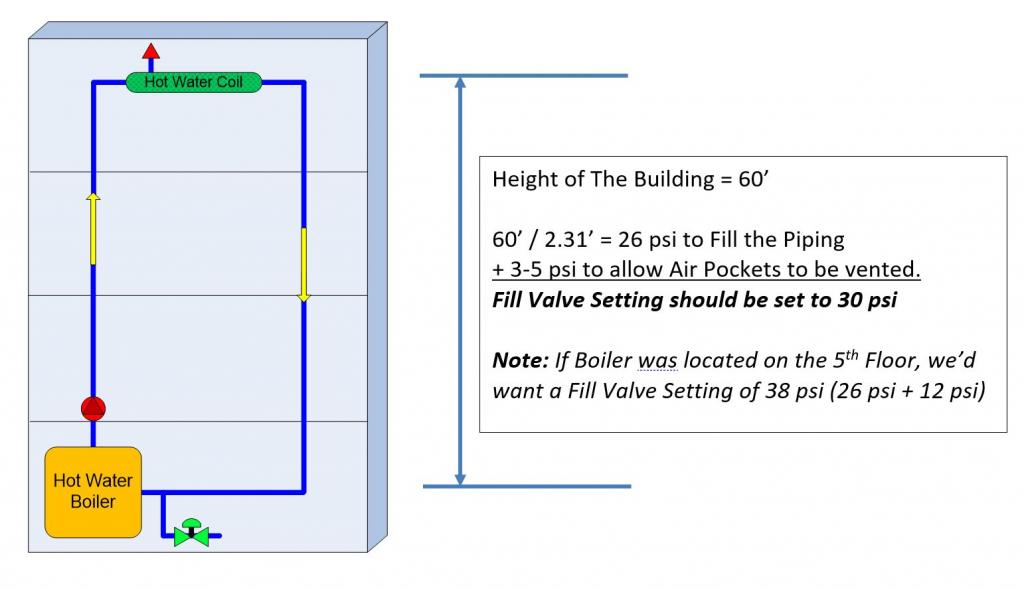

To fill a hydronic system, we need to know how tall the building is.

A few quick tips + Rules of Thumb:

- 1 psi = 2.31 feet

- 1 story = ~12 feet of elevation

- A Fill Valve is factory set at 12 psig, which is good for a 2-story residence.

- 3-5 psi of positive pressure is required at the top of our system to eliminate air pockets.

- A boiler and/or chiller, typically require a minimum water pressure of 12 psig.

Let’s take a look at a quick example. A 5-story Dormitory with the boiler located in the basement.

- 5 Stories x 12’/story = 60’ of vertical height.

- 60’ / 2.31 = 26 psi required to fill the piping.

- + 3-5 psi minimum pressure required at the top of the system.

- 26 psi + 3-5 psi would require ~30 psi of Fill Valve pressure in the basement.

Note: If the Boiler was at the Top of the system, we’d want to see 38 psi (26 + 12) Fill Valve pressure in the basement.

For the Rest of the Story:

On this Example, what happens when the contractor installs a standard Fill Valve and forgets to adjust the factory setting above 12 psig?

· You end up with a LOT of frustrated college students on the upper floors (4th & 5th) who get VERY cold in the middle of winter.

· After 10 years of complaints the college decided they needed a “new” boiler because of the endless complaints.

· Luckily a CHC Salesman was brought in to help evaluate the boiler replacement. After hearing the owner’s frustration, they were able to identify the incorrect setting on the Fill Valve which left the system partially filled with water.

· To make matters worse, the system pump was also operating backwards for 10 years.

Where freeze protection is a concern, we utilize a Glycol Make-up unit…in lieu of a Fill Valve. GMU’s are filled with premixed glycol and a pressure switch activates a pump to automatically + accurately control the minimum system fill pressure requirements. CHC has several options available for your system and glad to assist with sizing + pricing inquires.

If we can help you troubleshoot a building or residence that isn’t performing at it’s peak, we’re glad to assist. One of the first questions we should ask, is “what is your Fill Valve and/or GMU set for”? If you don’t know the answer, you may want to re-read this article. Ha!

Paul has been involved in many aspects of HVAC systems over the last 25 years, from design to troubleshooting to technical training. This experience, his quick wit, and humor makes him the perfect fit at CHC to lead our Corporate Training Program, and as an educator for our customers.

When Paul isn’t immersed in heating, cooling, and packaged systems solutions, he enjoys spending time with his family and friends. Can’t find Paul anywhere? Look behind the speeding boat that just passed you by, yep that was him cutting up the slalom course on a waterski. He’s also been known to jump out of a plane or off a 200’ bridge. You know, just for kicks.